Aywa: Where Technology Meets Craftsmanship in Wood and ACP CNC Cutting

October 21, 2019

From Concept to Creation: Aywa’s Advanced Waterjet Cutting for Marble, Granite, and More

May 7, 2025Precision and Power: Exploring Metal Laser Cutting, Base Plate Cutting, and Aluminium Panel Cutting at Aywa

At Aywa, we pride ourselves on delivering cutting-edge metal fabrication solutions that combine precision, efficiency, and versatility. Our advanced laser cutting services are tailored to meet the diverse needs of industries requiring intricate designs and high-quality finishes. In this blog, we’ll delve into the specifics of metal laser cutting, base plate cutting, and aluminium panel cutting, highlighting how our expertise can elevate your projects.

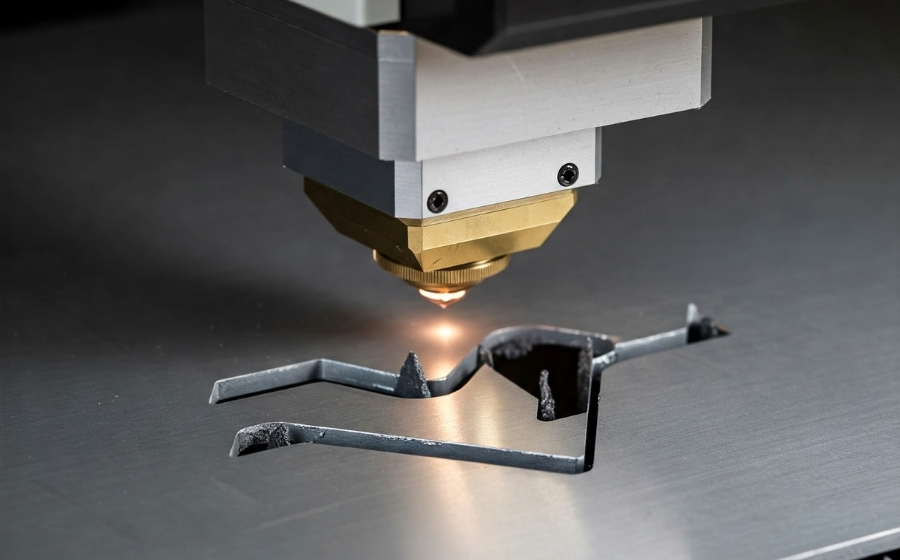

Metal Laser Cutting: Precision Meets Efficiency

Laser cutting is a non-contact process that utilizes a focused laser beam to melt, burn, or vaporize material, resulting in precise cuts with minimal material waste. This method is particularly advantageous for metals, offering high accuracy and the ability to create complex geometries.

Advantages of Metal Laser Cutting:

- High Precision: Achieves intricate designs with tight tolerances.

- Clean Edges: Produces smooth finishes, reducing the need for secondary processing.

- Material Versatility: Suitable for various metals, including steel, stainless steel, and aluminium.

- Efficiency: Faster cutting speeds compared to traditional methods, enhancing productivity.

- Our state-of-the-art laser cutting machines are equipped to handle a range of metal thicknesses, ensuring consistent quality across all projects.

Base Plate Cutting: Foundation of Structural Integrity

Base plates serve as critical components in structural applications, providing stability and support. Precision in cutting these plates is paramount to ensure proper alignment and load distribution.

Our Approach to Base Plate Cutting:

- Customized Solutions: Tailoring cuts to specific dimensions and hole patterns as per project requirements.

- Material Selection: Working with various grades of steel to match structural demands.

- Quality Assurance: Implementing rigorous inspection protocols to maintain structural integrity.

- By leveraging advanced laser cutting technology, we ensure that each base plate meets the exact specifications necessary for optimal performance in its intended application.

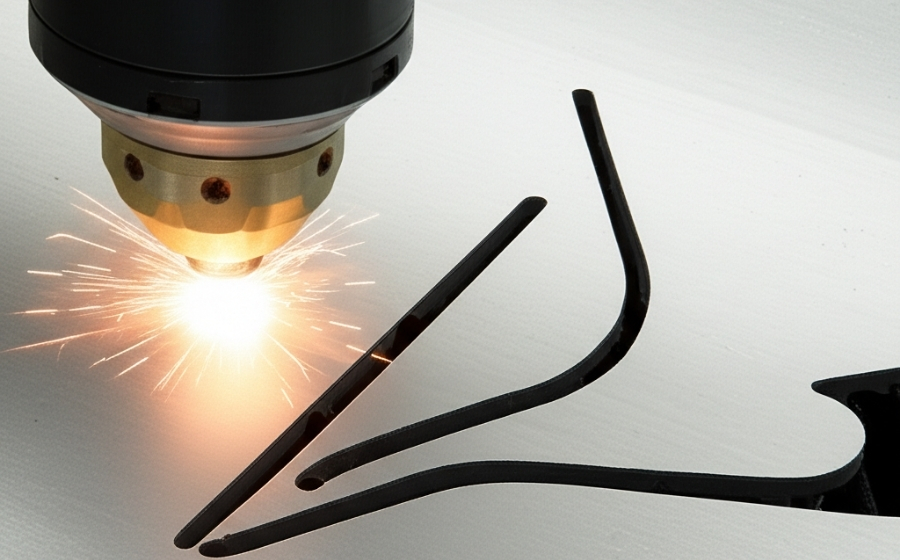

Aluminium Panel Cutting: Combining Lightness with Strength

Aluminium panels are widely used in industries such as automotive, aerospace, and architecture due to their lightweight and corrosion-resistant properties. Laser cutting aluminium requires precise control to prevent material deformation and achieve clean cuts.

Benefits of Laser Cutting Aluminium Panels:

- Minimal Thermal Distortion: The focused laser beam reduces heat-affected zones, preserving material properties.

- High-Speed Processing: Accelerates production timelines without compromising quality.

- Complex Designs: Enables the creation of intricate patterns and shapes for aesthetic and functional purposes.

- Our expertise in handling aluminium ensures that each panel is cut to perfection, meeting both structural and visual standards.

Why Choose Aywa for Your Laser Cutting Needs?

- Advanced Technology: Utilizing the latest laser cutting equipment for superior results.

- Skilled Professionals: A team of experienced technicians dedicated to precision and quality.

- Customer-Centric Approach: Collaborating closely with clients to understand and fulfill their unique requirements.

- Timely Delivery: Committed to meeting project deadlines without compromising on quality.

At Aywa, we are committed to delivering excellence in every cut. Whether you’re working on a large-scale industrial project or a bespoke design, our laser cutting services are designed to provide the precision and efficiency you need.

Contact us today to learn more about how our metal laser cutting, base plate cutting, and aluminium panel cutting services can contribute to the success of your next project.